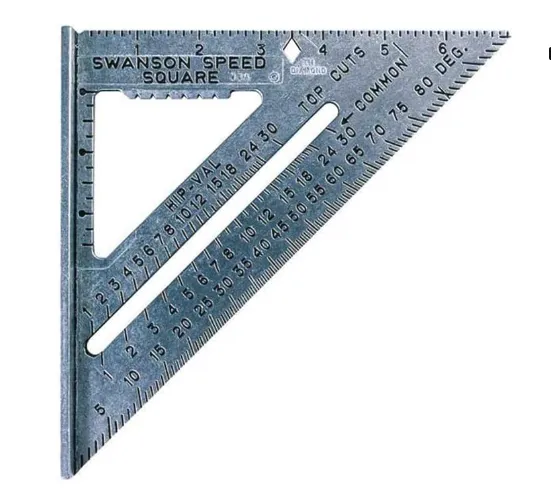

All the Tools You Need to

Install Permanent Christmas Lights

Master the Art of Permanent Christmas Lighting:

Essential Tools for Every Professional Installer

Welcome to the ultimate resource for your permanent Christmas lighting installation business!

Our carefully curated selection of tools is designed to provide you with everything you need to

build a successful and permanent lighting service, catering to both seasoned

professionals and those just starting in the industry.

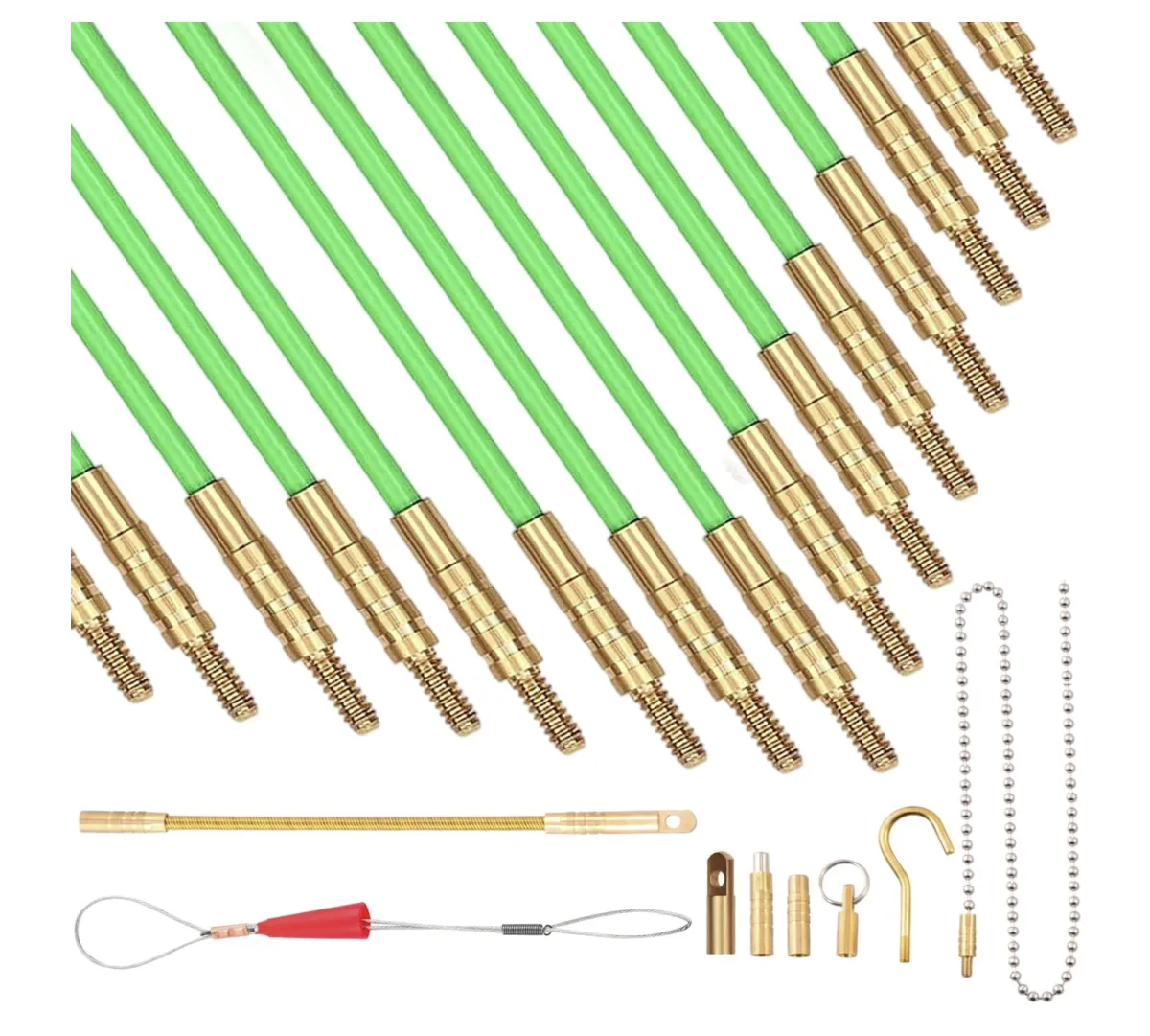

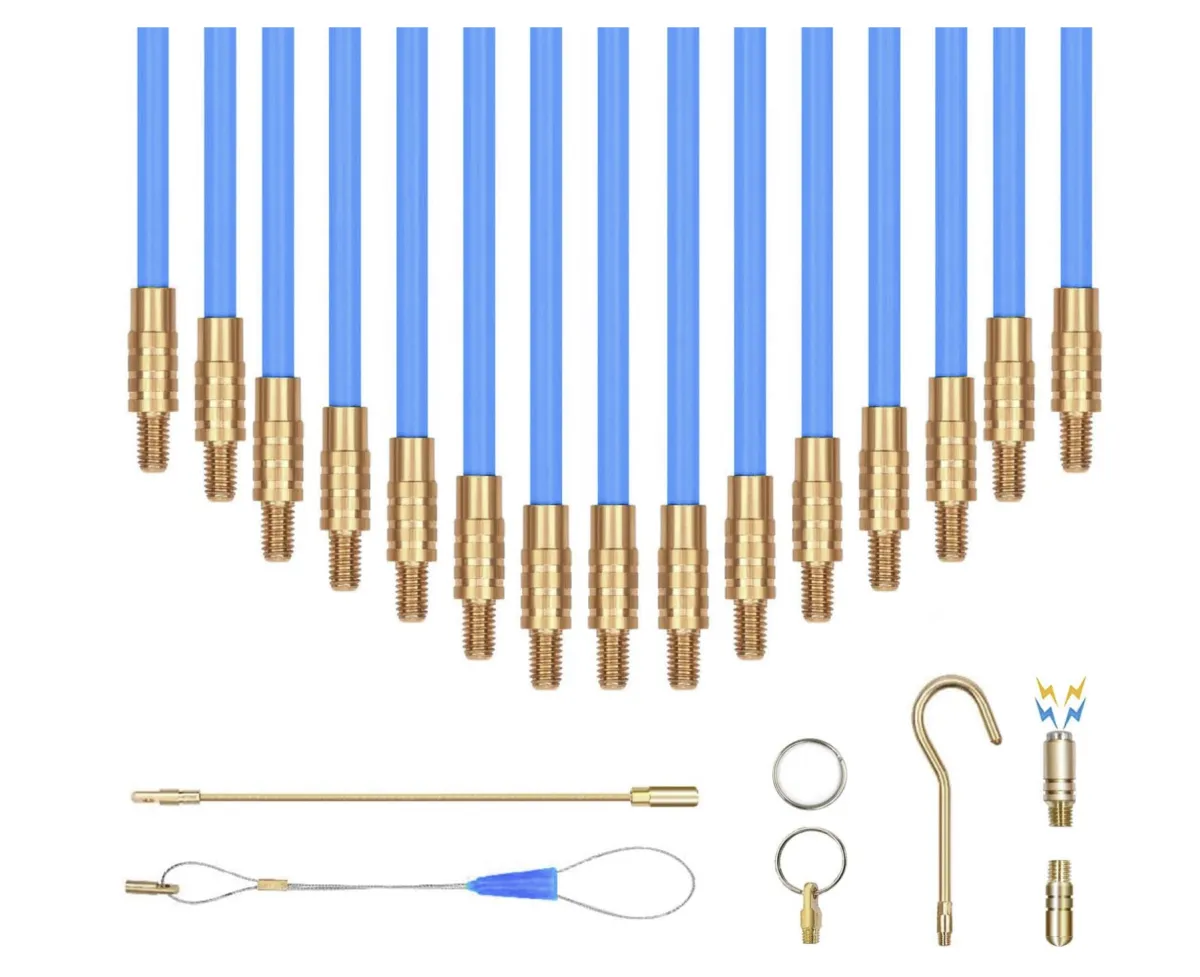

Boeray 11' Fiberglass Running Electrical Wire Cable Pulling Fish Tape Kit

Fiberglass better than Plated Carbon Steel, this fish tape will not break when folded, faster, easier pulls: low friction design allows the tape to easily glide through the conduit without binding at turns, joints or couplings;

Cougar Paws

Cougar Paws has been tested up to a 12/12 pitch; however, other measures must be taken for steeper pitches. The Peak Performer's 6" high uppers will protect you from rolling or stumbling as you make your ascent while still allowing the light coloration keep feet cool in hot sun conditions with asphalt roofs!

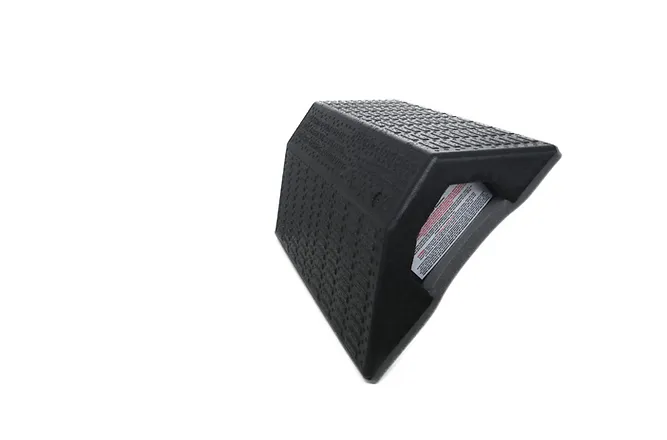

Pitch Hopper

The pitch hopper is a unique tool that allows you to get on any roof, no matter how high or steep it may be. It has many different variations so users can find one suitable for their needs- whether they want something quick with little effort or more challenging than what's been done before!

Elevate Your Permanent Christmas Lighting

Installations with Our Expert-Selected Tools

With these tools at your disposal, you're not just prepared to tackle any permanent installation challenge—you're equipped to excel. Our products are selected for their reliability, effectiveness, and ease of use, ensuring you can deliver exceptional, long-lasting results with every project. Whether you're expanding your services or just beginning your journey in the permanent Christmas lighting installation business, we're here to support your success every step of the way.

The Most Dangerous Christmas Light Install Mistakes

In the pressure washing and Christmas light installation industry, safety isn't just a buzzword—it's a matter of life and death. As someone who has witnessed numerous accidents and their aftermath, I want to address the critical importance of safety practices in our industry. Recent incidents, including several falls and tragic accidents, have highlighted the urgent need for better safety awareness and implementation.

The Real Cost of Cutting Corners

Let's talk numbers: A back surgery can cost upwards of $180,000 for the first procedure alone, with follow-up surgeries potentially reaching $260,000. But the real cost isn't just financial—it's the impact on your life, your family, and your ability to work. As the saying goes, "Falling won't kill you, but that sudden stop will." This harsh reality is why we need to take safety seriously, whether we're working one story up or three.

Essential Safety Equipment

Ladder Safety

1. Ladder Stabilizers: These aren't optional extras—they're essential safety equipment. A ladder standoff or stabilizer can prevent the ladder from kicking out, one of the most common causes of falls.

2. Proper Angle and Positioning:

- Maintain a 75-degree angle (the optimal ladder angle)

- Extend three rungs above the roof

- Ensure the ladder is on level ground

- Use ladder leg adjusters for uneven surfaces

3. Three Points of Contact: Always maintain three points of contact when climbing—this means two hands and one foot, or two feet and one hand should be in contact with the ladder at all times.

Roof Safety

1. Pitch Hoppers: While useful, these can give a false sense of security. Remember: you're either all on or all off—never straddle or partially use these tools.

2. Harness Systems:

- Basic harness kit ($100-150)

- Goat Assist ($500-600)

- Ridge Pro ($600)

- Professional rope systems

3. Cougar Paws: Specialized footwear for better roof traction.

Electrical Safety in Christmas Light Installation

Electrical safety is just as crucial as fall protection. Here are key guidelines:

1. One Male End Rule: Only one male plug per line—you can have multiple female connections, but never multiple male ends.

2. Proper Connection Protection:

- Use female ends at termination points

- Position connections to allow water drainage

- Avoid using tape on connections as it can trap water

- Use clips to secure connections away from gutters

3. Power Management:

- Use remote controls for testing

- Always cut wires with power off

- Test installations systematically to avoid multiple trips

Best Practices for Working at Height

Before You Start

1. Look Up: Always check for power lines before setting up ladders or equipment.

2. Sound the Roof: Check for weak spots or rotted areas before walking on any roof.

3. Have a Fall Plan: Know where you could catch yourself or what you might grab if you start to fall.

During Work

1. Never Work Alone: Always have someone who can call 911 if needed. A real-life example: a pressure washer fell from a 6-foot deck, broke his back, and had to crawl to his truck to call for help because he was working alone.

2. Keep Your Phone on You: Carry your cell phone in a secure pocket while working.

3. Weather Awareness: Avoid roof work in wet, icy, or frosty conditions. Even morning dew can make surfaces dangerously slick.

Training and Certification

Investment in safety training is far less expensive than hospital bills or funeral costs. Consider:

1. OSHA 10 Certification: Especially important for rope and harness work.

2. Professional Safety Courses: Many companies offer specialized training for roof work and fall protection.

3. Regular Safety Meetings: If you have employees, document safety training and have workers sign off on procedures.

Special Considerations

Weather Conditions

- Never work on icy or frost-covered roofs

- Be aware that morning dew can create slippery conditions

- Wind can make ladder work particularly dangerous

Employee Safety

Remember that employees often try to exceed what they see you do—if you work unsafely, they may take even bigger risks. Set a good example by always following safety protocols, even for quick tasks.

Equipment Maintenance

- Regularly inspect all safety equipment

- Replace any worn or damaged items immediately

- Keep ladders clean and in good condition

- Check electrical equipment for wear or damage

Common Mistakes to Avoid

1. Overconfidence: Many accidents happen to experienced workers who become too comfortable with risks.

2. Rushing: Never compromise safety to complete a job faster or to squeeze in one more task.

3. Inadequate Equipment: Don't try to make do with improper tools or worn-out safety gear.

4. Working Alone: Always have a spotter for ladder work and someone available to call for help if needed.

The Business Case for Safety

While safety equipment and proper training represent an investment, consider the alternatives:

- Hospital bills ranging from tens to hundreds of thousands of dollars

- Lost work time and income

- Potential business closure due to injury

- Legal liability and increased insurance costs

Moving Forward: Building a Culture of Safety

As our industry continues to grow, with more people entering both pressure washing and Christmas light installation businesses, it's crucial to establish and maintain a strong safety culture. This means:

1. Regular Training: Invest in ongoing safety education for yourself and your team.

2. Proper Equipment: Budget for and maintain quality safety gear.

3. Clear Procedures: Establish and document safety protocols for all aspects of your work.

4. Zero Tolerance: Never compromise on safety for convenience or profit.

Remember, no job is worth risking your life or long-term health. The few extra minutes it takes to set up proper safety equipment, or the additional cost of quality safety gear, is insignificant compared to the potential consequences of an accident. As we continue to see accidents in our industry, let's commit to making safety our top priority and looking out for one another. After all, the best job is one that you can walk away from at the end of the day.

Whether you're new to the industry or a seasoned professional, take this message to heart: Safety isn't just about following rules—it's about going home to your family every night. Make the commitment to safety today, because tomorrow might be too late.

What is the correct angle for positioning a ladder?

A: The optimal ladder angle is 75 degrees. A good rule of thumb is the "one-quarter rule" - the ladder's base should be placed one-quarter of the ladder's working length away from the wall. For example, if you're climbing to a 12-foot height, the base of the ladder should be 3 feet from the wall. Additionally, make sure the ladder extends at least three rungs above the roof line for safe access.

Do I really need a ladder stabilizer?

A: Yes, ladder stabilizers are essential safety equipment, not optional extras. They prevent the ladder from kicking out, which is one of the most common causes of falls. A ladder stabilizer (or standoff) also helps protect gutters and provides better stability when accessing the roof. The cost of a stabilizer is minimal compared to potential medical bills from a fall.

When should I use a safety harness on a roof?

A: You should consider using a safety harness any time you're working on a roof, regardless of the pitch or height. While there's no specific pitch requirement that mandates harness use, remember that falls can happen even on seemingly "safe" low-slope roofs. A basic harness kit costs $100-150, a small investment compared to the potential cost of injury. More advanced systems like the Goat Assist ($500-600) or Ridge Pro ($600) provide additional safety features.

What's the proper way to handle electrical connections for Christmas lights?

A: Follow these key rules for electrical safety:

- Always have only ONE male plug per line

- Use female ends at termination points

- Position connections pointing down and away from gutters to allow water drainage

- Never use tape on connections as it can trap water

- Use clips to secure connections away from gutters

- Always cut wires with the power off

- Use a remote control for testing installations

Why shouldn't I work alone on ladder or roof jobs?

A: Working alone creates significant risks. If you fall or get injured, you need someone to call 911 immediately. There's a real example of a pressure washer who fell from just a 6-foot deck, broke his back, and had to crawl to his truck to call for help because he was working alone. Your spotter can also foot the ladder, watch for hazards, and help with equipment. Always have someone who can call for emergency help if needed.

What should I check before getting on a roof?

A: Before accessing any roof:

1. Look up to check for power lines

2. Sound the roof to check for weak spots or rotted areas

3. Assess weather conditions - avoid wet, icy, or frosty conditions

4. Ensure your ladder is properly positioned and secured

5. Have your safety equipment ready and properly fitted

6. Make sure you have a spotter present

7. Keep your phone on you for emergencies

What are the most common safety mistakes people make?

A: The most frequent safety mistakes include:

- Overconfidence/complacency, especially among experienced workers

- Rushing to complete jobs or "just one more task"

- Using inadequate or worn-out safety equipment

- Working alone without a spotter

- Not maintaining three points of contact on ladders

- Improper ladder positioning

- Not using ladder stabilizers

- Trying to reach too far instead of moving the ladder

How should I store and maintain my safety equipment?

A: Proper maintenance of safety equipment is crucial:

- Regularly inspect all safety equipment before each use

- Replace any worn or damaged items immediately

- Keep ladders clean and free from debris

- Store equipment in a dry place

- Document inspections and repairs

- Never use damaged equipment "just one more time"

- Follow manufacturer guidelines for replacement schedules

What safety training should I invest in?

A: Recommended safety training includes:

- OSHA 10 certification, especially if using rope and harness systems

- Professional safety courses specific to roof work

- Fall protection training

- Ladder safety certification

- Electrical safety training for Christmas light installation

- Regular safety meetings and updates for teams

- First aid and emergency response training

How much should I budget for safety equipment?

A: While safety equipment requires an investment, consider these typical costs versus potential medical bills:

- Basic harness kit: $100-150

- Goat Assist: $500-600

- Ridge Pro: $600

- Ladder stabilizers: $50-100

- Quality extension ladder: $200-400

- Cougar Paws (roof boots): $100-200

- Remote power controls: $50-100

- First aid kits: $50-100

Remember: A single back surgery can cost $180,000 or more. Even the most expensive safety equipment is a bargain compared to medical bills, lost work time, or worse. Investment in proper safety equipment should be considered a necessary business expense, not an optional extra.

Copyright ©2025 All Right Reserved website designed by christmaslights.io

Terms of Service / Privacy Policy

Have questions or need assistance?

Contact us at (855)619-LITE