Secure your Christmas lights effortlessly with our selection of professional grade clips

Secure Your Shine: Professional-Grade Christmas Light Clips for Every Surface

Click on any category below to jump directly to that section

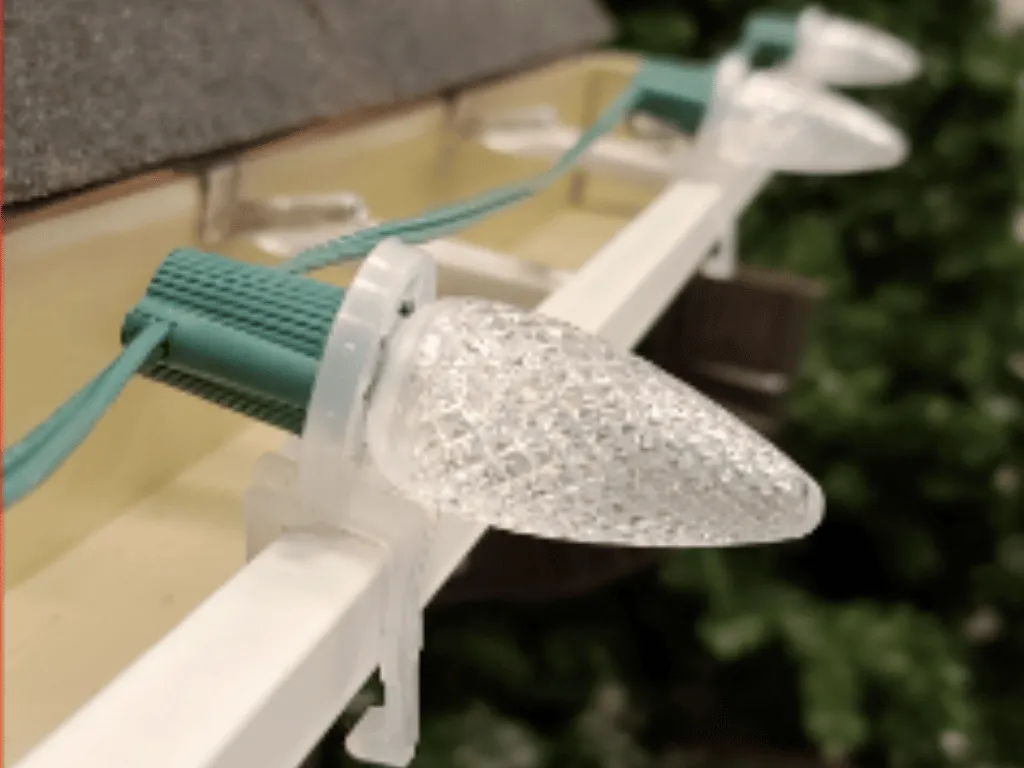

Sturdy clips designed specifically for larger C9 bulbs. Perfect for rooflines and creating bold, visible displays.

Versatile clips tailored for medium-sized C7 bulbs. Ideal for various applications, from windows to outdoor structures.

Christmas Light Clips: Innovative clips with strong magnets for easy, damage-free installation on metal surfaces like gutters and downspouts.

Specialized clips for secure attachment along roof ridges and peaks, ensuring a perfectly straight light line on difficult angles.

Convenient pre-spaced clip strips for quick and uniform installation of light strings, saving time and effort.

Unique clips designed for specific surfaces or applications, such as brick, stucco, or wrapping lights around columns.

C9 Christmas Light Clips

C7 Christmas Light Clips

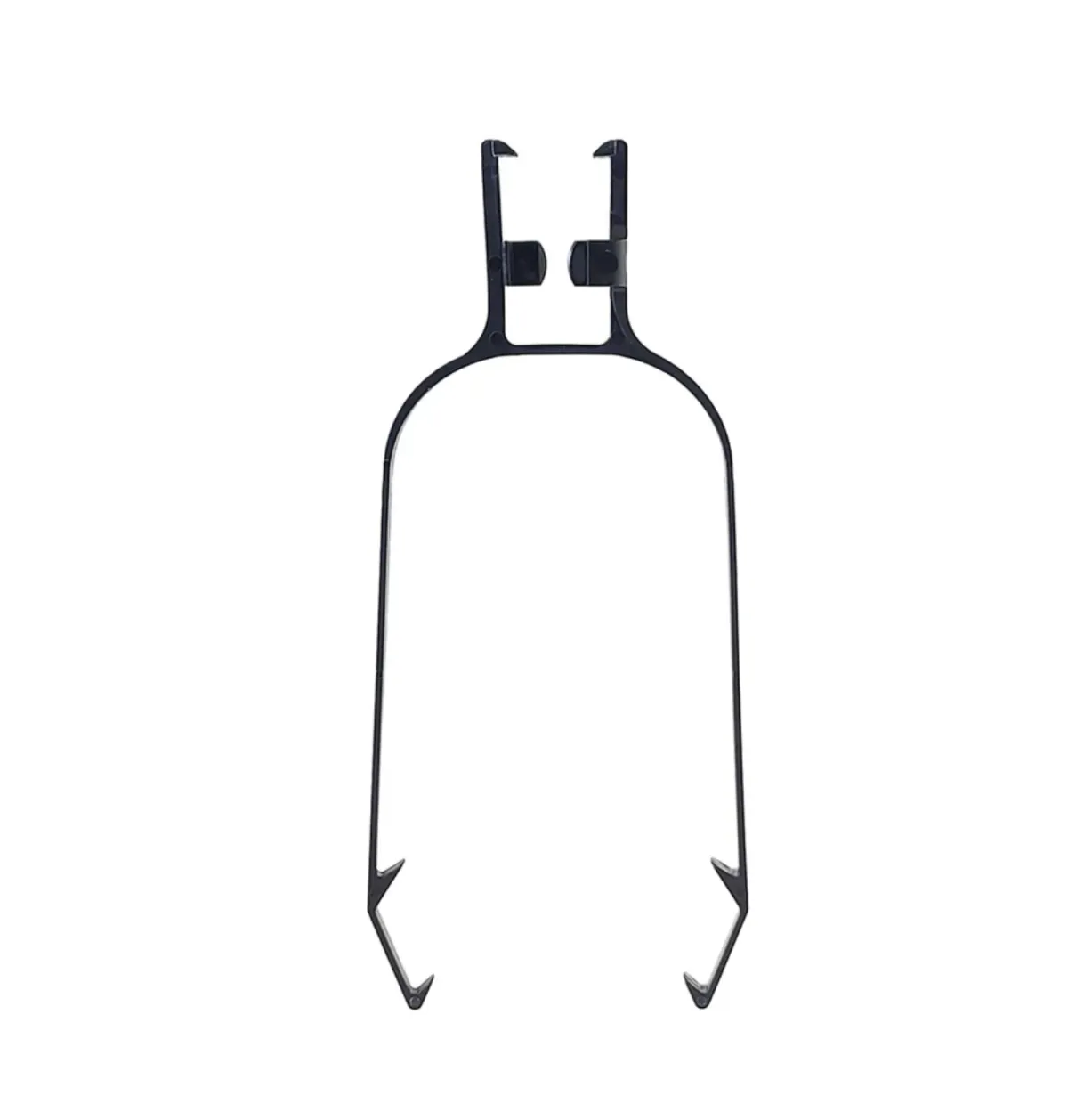

Christmas LiteClip & Strips

Streamline your holiday light installation with our commercial-grade LiteClips. Available for both C9 and C7 bulbs, these versatile clips easily secure between the socket and bulb, allowing for downward, upward, or straight-out positioning. For a complete, safe, and secure setup, pair with our LiteClipStrip mounting system. These efficient tools ensure quick and professional-looking installations for homes and businesses alike. Available in White or Brown.

Speciality Christmas Lights Clips

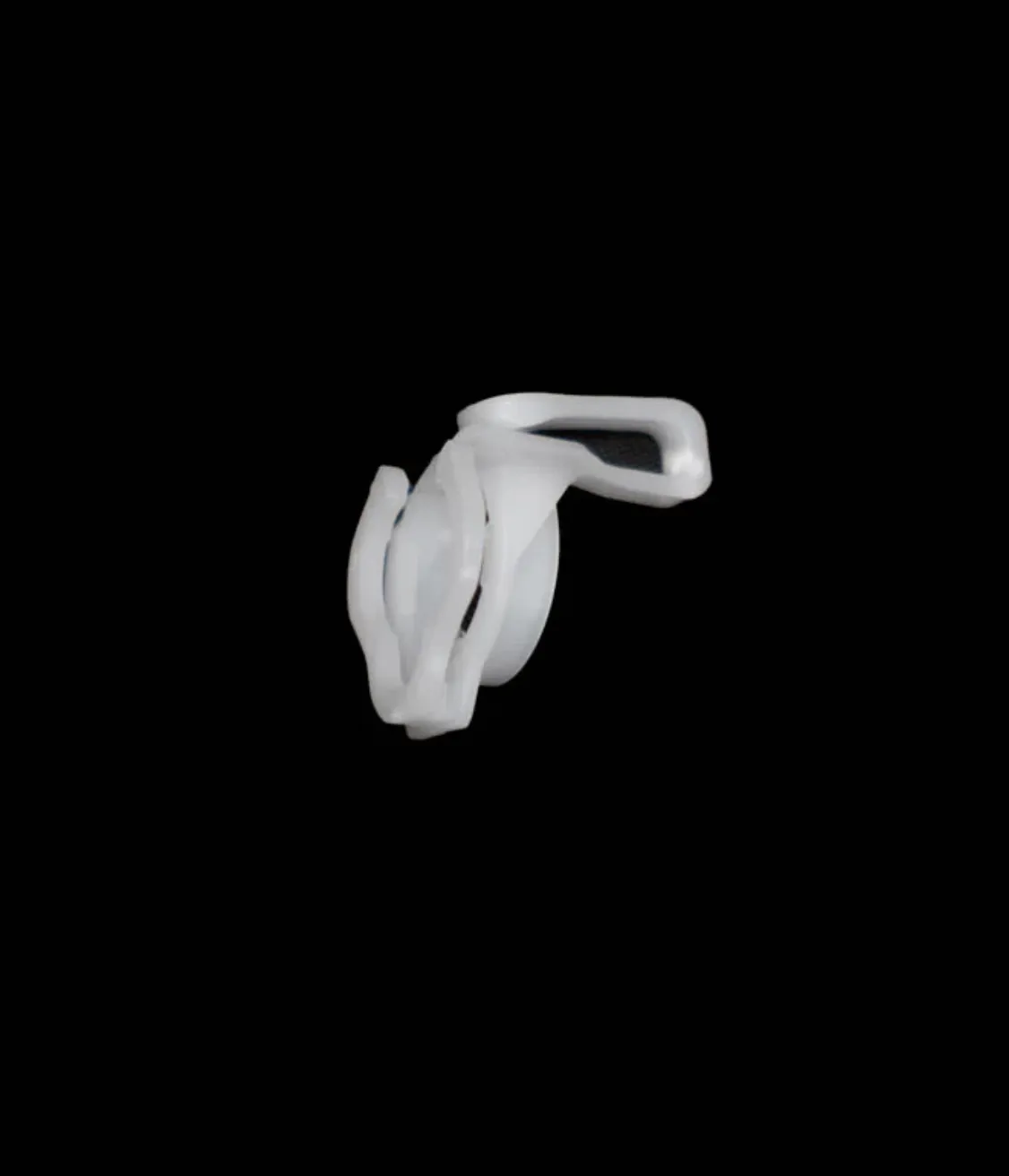

All-Purpose

Clip

The All-in-One Plus clip, favored by professional installers, accommodates C7, C9, C6, mini, and icicle lights, offering versatile horizontal gutter and vertical shingle mounting options, a tight grip for mini lights, layering capabilities for unique designs, and the ability to hang two light strings simultaneously, ensuring a perfect roof display.

Best Shingle

Tab Clip

This durable plastic shingle tab, more robust than standard versions, securely holds both C7 and C9 sockets, easily slides under shingles, and versatilely attaches to gutters, decks, and flat surfaces (when paired with a parapet clip), making it the perfect Christmas light accessory for various installation needs.

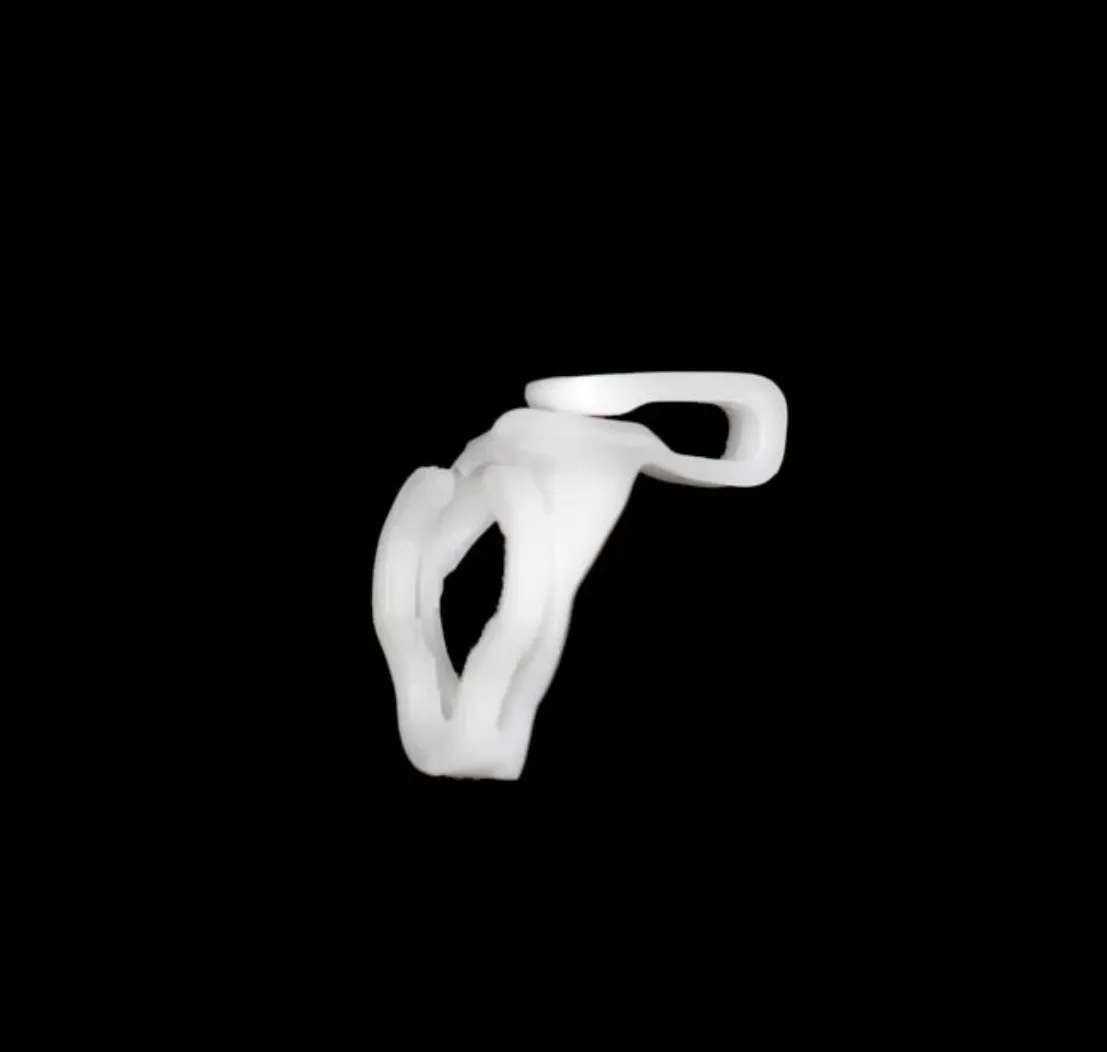

Tuff Tab

Clip

The durable Tuff Tabs, designed for C7 or C9 bulbs, feature Flex technology for easy installation over socketed bulbs, 360-degree rotation, outward-facing positioning on shingles or cedar shakes, two living hinges for secure hold, and weather-resistant construction for professional-grade Christmas light displays.

Christmas Light Ridge Clips

C9/C7 Best Enclosed

Ridge Clip

The C9/C7 Best Enclosed Ridge Clip (Patent Pending) is a durable, year-round solution for C7 and C9 socket strands and bulbs, featuring a fully enclosed design that securely holds lights in place without detachment, making it ideal for permanent or long-term installations.

Magnetic Christmas Lights Clips

Magnet Clip for C7/C9

Socket Wire

The Magnetic Clip for C7 or C9 Sockets, designed exclusively for SPT-1 wire (not compatible with LED stringer sets), features a high-strength solid magnet that securely holds lights horizontally or vertically on metal surfaces (excluding aluminum), allowing for quick, reusable installations year after year.

C9 Magnetic Spool

12" Spacing

This versatile lighting solution features heavy-duty, UV-protected 18-gauge SPT-1 wire rated for 840 watts, equipped with rust-resistant nickel-plated C9 magnetic sockets for secure attachment to ferrous metals, 12" spacing, 250' or 500' foot spool, compatible with E17 base incandescent and LED bulbs (sold separately), and suitable for both indoor and outdoor use.

C9 Magnetic Spool

15" Spacing

This versatile lighting solution features heavy-duty, UV-protected 18-gauge SPT-1 wire rated for 840 watts, equipped with rust-resistant nickel-plated C9 magnetic sockets spaced 15" apart on 250' or 500' spools, securely attaching to ferrous metals and compatible with E17 base incandescent and LED bulbs (sold separately) for both indoor and outdoor use.

Why Christmas Light Clips Are a Game-Changer

Transform your holiday decorating experience with professional-grade Christmas light clips. These versatile tools are the secret to creating clean, polished displays that withstand the elements all season long. Designed for various surfaces and bulb sizes, quality clips ensure your lights stay securely in place, avoiding the sloppy appearance and frequent adjustments often associated with cheaper alternatives. Easy to install and remove, these clips are favored by professionals nationwide for their durability and neat finish. By investing in commercial-grade clips, you'll save valuable time during both setup and takedown, allowing you to focus more on enjoying the festive season rather than fussing with your decorations. Make your holiday lighting effortless and impressive with the right clips, and elevate your display to a professional standard with minimal hassle.

Christmas Light Clips

for Damage-Free, Professional Displays

Upgrade your holiday decorating technique by replacing staple guns and nails with versatile Christmas light clips. These innovative tools not only protect your home and lights from damage but also allow for easy adjustments after installation. Available in various designs to suit different surfaces like gutters, shingles, and flat areas, light clips can securely hold multiple bulb sizes, including C7, C9, icicle, and mini lights. By switching to clips, you'll preserve your property's integrity, extend the life of your lights, and gain the flexibility to perfect your holiday illumination with ease. Embrace this simple yet effective solution to elevate your decorating process and achieve professional-looking results without the hassle and potential harm of traditional fastening methods.

Frequently Asked Questions

How do Christmas light clips compare to traditional methods like staples or nails?

Christmas light clips are superior to staples or nails because they don't damage your home or lights, allow for easy adjustments and removal, and provide a cleaner, more professional look. They also make it easier to reuse your lights year after year without causing additional wear and tear.

Can using Christmas light clips save time during installation and removal?

Yes, using Christmas light clips can significantly reduce setup and takedown time. They're designed for easy installation and removal, allowing you to spend less time on decorating and more time enjoying the holiday season.

How do Christmas light clips improve the longevity of my holiday lights?

By securely holding your lights in place without pinching or damaging the wires, Christmas light clips help extend the life of your holiday lights. They also protect lights from harsh weather conditions, reducing the need for frequent replacements.

How do professional-grade Christmas light clips contribute to a better overall display?

Professional-grade clips ensure your lights stay in place, creating a neat and uniform appearance. They allow for precise positioning and spacing of lights, resulting in a polished, high-quality display that enhances your home's festive appeal.

What surfaces can Christmas light clips be used on?

Christmas light clips are designed for use on various surfaces, including gutters, shingles, and flat areas. There are also specialized clips for different applications, such as ridge clips and all-purpose clips.

How do Christmas light clips benefit holiday decorating?

Christmas light clips offer several benefits: they protect your home and lights from damage, allow for easy adjustments after installation, work on various surfaces, securely hold multiple bulb sizes, and help achieve a professional-looking display without the hassle of traditional fastening methods.

Discover Expert Tips on Our Blog

Deck the Halls Without the Falls: A Comprehensive Guide to Fall Protection for Christmas Light Installers

As a professional Christmas light installer, your job is to bring joy and holiday cheer to homes and businesses. However, this line of work comes with inherent risks, particularly when it comes to working at heights. Falls are a leading cause of injuries and fatalities in the construction industry, and Christmas light installers are no exception. In this blog post, we'll explore essential fall protection strategies to help keep you safe on the job.

Understanding the Risks

Before we dive into fall protection strategies, it's crucial to understand the risks involved in Christmas light installation. Common causes of falls include overreaching, improper ladder use, and lack of proper equipment. According to the Occupational Safety and Health Administration (OSHA), falls account for nearly one-third of all construction-related fatalities. The consequences of a fall can be severe, ranging from broken bones and head injuries to permanent disability and even death. Additionally, falls can lead to legal issues and financial losses for both the installer and the company.

Proper Equipment

One of the most important aspects of fall protection is using the proper equipment. A Personal Fall Arrest System (PFAS) is a must-have for any Christmas light installer working at heights. A PFAS consists of three main components: a harness, a lanyard, and an anchor point. The harness should fit snugly and be worn correctly, with the straps adjusted to distribute weight evenly. The lanyard connects the harness to the anchor point and should be short enough to prevent the worker from hitting the ground in case of a fall. The anchor point must be strong enough to support the weight of the worker and the fall arrest system.

Ladders are another essential piece of equipment for Christmas light installers. Choosing the right ladder for the job is crucial. Stepladders are suitable for shorter heights, while extension ladders are better for reaching higher elevations. When using a ladder, always follow safety guidelines, such as maintaining three points of contact, keeping the ladder on level ground, and avoiding overreaching.

For larger projects or hard-to-reach areas, scaffolding or lifts may be necessary. There are various types of scaffolding and lifts available, each with its own safety guidelines. Always follow the manufacturer's instructions and OSHA regulations when using scaffolding or lifts.

Training and Education

Proper training and education are essential for ensuring the safety of Christmas light installers. OSHA requires employers to provide fall protection training to workers exposed to fall hazards. This training should cover topics such as identifying fall hazards, using fall protection equipment, and following safe work practices. In-house training programs can be tailored to the specific needs of the company and its employees.

Continuing education and refresher courses, such as those offered by Christmaslights.io: Online & In-Person Christmas Lights Training and Supplies are crucial for Christmas light installers to maintain their skills and stay informed about the latest safety regulations in the industry. These training programs help professionals keep their knowledge fresh, learn about new techniques and equipment, and ensure they are following best practices on the job. Employers should prioritize and support ongoing training for their Christmas light installers to foster a culture of safety, reduce the risk of accidents, and maintain a highly skilled workforce.

Job Site Assessment and Planning

Before starting any Christmas light installation project, it's essential to conduct a thorough job site assessment. This involves identifying potential fall hazards, such as unstable surfaces, overhead power lines, and weather conditions. Based on the assessment, a fall protection plan should be developed, outlining the specific equipment and procedures needed to mitigate the identified risks.

Communication and coordination with the entire team are crucial during the planning phase. Everyone involved in the project should be aware of the fall protection plan and their individual roles and responsibilities.

Best Practices During Installation

During the actual installation process, Christmas light installers must follow best practices to ensure their safety. This includes properly using fall protection equipment, following safe ladder usage techniques, and maintaining three points of contact when climbing or descending.

Working in pairs or teams can also enhance safety, as co-workers can spot each other and provide assistance in case of an emergency. It's important to manage fatigue and take regular breaks to avoid mistakes and accidents caused by exhaustion.

Emergency Response and Rescue

Despite our best efforts, accidents can still happen. That's why it's crucial to have an emergency response plan in place. This plan should outline the steps to take in case of a fall or other emergency, including contacting emergency services and providing first aid.

All employees should be trained on emergency procedures and know their roles in the event of an incident. Providing first aid and CPR training to team members can also be lifesaving. Coordination with local emergency services, such as fire departments and ambulance services, can help ensure a swift and effective response in case of an emergency.

Maintenance and Inspection

Fall protection equipment is only effective if it's well-maintained and inspected regularly. Employers should establish a schedule for inspecting harnesses, lanyards, and anchor points, looking for signs of wear, damage, or defects. Any equipment that shows signs of deterioration should be removed from service immediately and replaced.

Proper storage and care of equipment can also extend its lifespan and ensure it's ready for use when needed. Documenting inspections and maintenance can help track the condition of equipment and identify any patterns or issues that need to be addressed.

Creating a Culture of Safety

Ultimately, the success of any fall protection program depends on creating a strong culture of safety within the organization. Management must lead by example, prioritizing safety in all aspects of the business. This includes providing the necessary resources, such as equipment and training, and regularly communicating the importance of safety to employees.

Encouraging employee participation and feedback can also foster a sense of ownership and responsibility for safety. Recognizing and rewarding safe behavior, such as through incentive programs or public acknowledgment, can reinforce the importance of following safety protocols.

Continuously improving safety practices through regular reviews, incident investigations, and employee input can help identify areas for improvement and ensure that the fall protection program remains effective over time.

As a professional Christmas light installer, your safety should always be a top priority. By understanding the risks, using proper equipment, receiving adequate training, and following best practices, you can significantly reduce the likelihood of falls and other accidents on the job.

Remember, fall protection is not a one-time event but an ongoing process that requires commitment from everyone in the organization. By implementing these essential fall protection strategies and creating a strong culture of safety, you can ensure that you and your colleagues go home safely at the end of each day, ready to spread more holiday cheer.

Q: What are the common causes of falls during Christmas light installation?

A: Common causes of falls include overreaching, improper ladder use, and lack of proper equipment.

Q: What is a Personal Fall Arrest System (PFAS), and what are its components?

A: A PFAS is a must-have for any Christmas light installer working at heights. It consists of three main components: a harness, a lanyard, and an anchor point.

Q: What should I consider when choosing a ladder for Christmas light installation?

A: When choosing a ladder, consider the height you need to reach. Stepladders are suitable for shorter heights, while extension ladders are better for reaching higher elevations. Always follow safety guidelines when using ladders.

Q: What does OSHA require in terms of fall protection training for workers?

A: OSHA requires employers to provide fall protection training to workers exposed to fall hazards. This training should cover topics such as identifying fall hazards, using fall protection equipment, and following safe work practices.

Q: Why is job site assessment important before starting a Christmas light installation project?

A: A thorough job site assessment helps identify potential fall hazards, such as unstable surfaces, overhead power lines, and weather conditions. This information is essential for developing a fall protection plan and ensuring worker safety.

Q: What are some best practices to follow during Christmas light installation?

A: Best practices include properly using fall protection equipment, following safe ladder usage techniques, maintaining three points of contact when climbing or descending, working in pairs or teams, and managing fatigue by taking regular breaks.

Q: Why is it crucial to have an emergency response plan in place?

A: Despite best efforts, accidents can still happen. An emergency response plan outlines the steps to take in case of a fall or other emergency, including contacting emergency services and providing first aid. It ensures a swift and effective response in case of an incident.

Q: How often should fall protection equipment be inspected?

A: Employers should establish a schedule for inspecting harnesses, lanyards, and anchor points, looking for signs of wear, damage, or defects. Any equipment that shows signs of deterioration should be removed from service immediately and replaced

Q: Why are continuing education and refresher courses important for Christmas light installers?

A: Continuing education and refresher courses help Christmas light installers maintain their skills, stay informed about the latest safety regulations, learn about new techniques and equipment, and ensure they are following best practices on the job.

Q: What kind of training programs are available for Christmas light installers?

A: Training programs like those offered by Christmaslights.io: Online & In-Person Christmas Lights Training and Supplies provide Christmas light installers with opportunities for continuing education and refresher courses.

Q: How do these training programs benefit professionals in the Christmas light installation industry?

A: These training programs help professionals keep their knowledge fresh, learn about new techniques and equipment, and ensure they are following best practices on the job.

Q: What role should employers play in supporting ongoing training for their Christmas light installers?

A: Employers should prioritize and support ongoing training for their Christmas light installers to foster a culture of safety, reduce the risk of accidents, and maintain a highly skilled workforce.

Q: What are the benefits of employers investing in ongoing training for their Christmas light installers?

A: By investing in ongoing training, employers can foster a culture of safety, reduce the risk of accidents, and maintain a highly skilled workforce in the Christmas light installation industry.

Copyright ©2025 All Right Reserved website designed by christmaslights.io

Terms of Service / Privacy Policy

Have questions or need assistance?

Contact us at (855)619-LITE