Invisilights

Permanent Holiday Lighting

Customizable Lights for Any Event

WHAT YOU NEED TO KNOW BEFORE ORDERING

Total Linear footage of the installation.

This should include footage of lights and channel along with any Extensions or jumps you'll need to make

Where your controller box will be located

This is the most important step to planning out an installation, Without knowing where the controller will be you'll have no way to know the right materials to buy when it comes to extensions and accessories.

What Voltage system you want to use 24V or 36V

This is a decision you will make based on convince and efficiency, the most important factor with this will be the footage of each lighting run. If the total footage of a run is over 100' you'll need to either power inject on that run or switch to the 36V system that can go up to 200' before needing power injection.

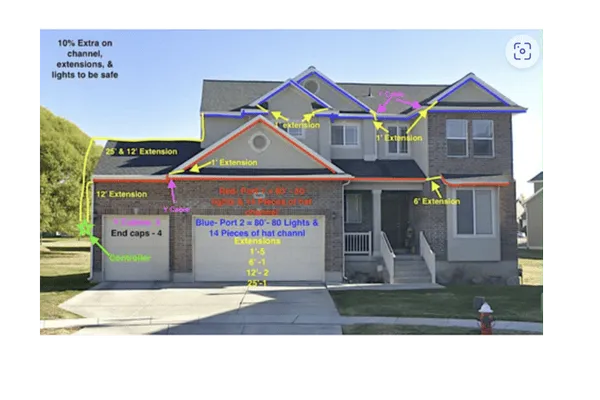

Draw a Map

By mapping out the installation you'll be able to better understand and plan out the install giving you a better idea of what all you'll need to purchase to complete the job.

take the measurements from your map and add up the total number of materials you'll need.

For the Map out example above the total material breakdown is:

System Voltage: 36V

Color of channel: Cameo

Channel Type: Hat

Total Lighted Footage: 160'

Power injection: NO

Controller: 1

Channel: 27- 6' sticks

Screws- 200

Lights: 175

1' extensions-7

6' Extensions-2

12' extensions-2

25- extensions- 1

Y Cables- 3

End caps- pack of 10

Absolute necessities

-Controller

-Lights

-Channel

-Screws

-Extension cables

Other Accessories

-Y Cable

-End Caps

- Signal boosters

-Power injection material

When would you need to power inject?

The controller will come with 3 outputs for your lighting runs, each 36V output can do a Max of 200', the 24V system can do a max of 100'. After that max you'll need to inject power. After you do so you can go an additional 100' with the 24V or 200' with the 36V system.

Power injection is needed due to voltage drop, voltage drop happens due to the length traveled away from the power source along with the gauge of the wire. due to the gauge of wire the lights and extensions run on it drops in voltage enough at 100' with the 24V system and 200' with the 36V system to effect the lights performance requiring a addition of power (Power Injection)

Materials needed for power injection 36V

Power injection pig female pig tale

Power injection Extension cables

Power injection T Cable.

Materials needed to Power inject 24V

16/2 - 12/2 Low voltage landscaping wire

Cut and Splice T cable

Water Proof Wire connectors

Discover the Transformative Power of Invisilights: Expertly Installed Permanent Lighting Solutions

Enhance your installation offerings with Invisilights, the premier permanent lighting solution designed for seamless integration into any property’s exterior architecture.

Crafted with high-quality aluminum channels and advanced LED technology, Invisilights delivers durability and superior energy efficiency—key selling points for your clients seeking long-lasting, cost-effective lighting solutions. Our system not only provides brilliant illumination but also boosts the aesthetic appeal and functionality of any home.

Offer your clients peace of mind with our robust 5-year warranty, ensuring reliable performance and minimal maintenance needs. This warranty supports your commitment to quality and customer satisfaction, making it easier for you to sell and install with confidence.

Our flexible, programmable system allows you to meet any client’s specific desires—from subtle accents to full-scale holiday displays—making it an adaptable choice for various applications. With Invisilights, you can cater to a wide range of preferences and needs, increasing your market reach and customer retention.

Choose Invisilights for your installations and add a transformative product to your portfolio that will impress clients and ensure your services remain in demand for years to come.

Frequently Asked Questions

What exactly comes in the 150' InvisiLights permanent outdoor lighting kit?

The InvisiLights kit is comprehensively equipped to ensure you have everything you need for installation. Each kit includes:

27 sticks of 6-foot Aluminum Channel to house and protect the lighting elements.

150 feet of dynamic RGBW LED Lights, which includes 23 sets of 6-count and 14 sets of 1-count lights, allowing for extensive coverage and diverse configuration options.

2 Data Boosters to enhance signal strength across the lighting installation, ensuring consistent control and color output.

A 320W Power Supply capable of supporting up to 190 puck lights, providing ample power for even the most extensive setups.

1 GFCI Outlet Adapter to ensure safe outdoor electrical connections.

1 Controller that allows you to manage and customize the lighting effects easily.

Will I need any additional components besides what's included in the Invisilights permanent lighting kit?

While the Invisilights kit comes with all the essential components for a standard installation, there are a couple of scenarios where you might need additional items:

Jumper Wires: Depending on the layout of your installation and the number of gaps or 'jumps' between the sections of lights, you may require jumper wires. These wires help bridge the gaps without losing the continuity of the light sequence, ensuring a smooth and uniform display across more complex architectures.

Data Boosters: If any section of your lighting setup is more than 15 feet away from the control box, additional data boosters will be necessary. Data boosters help maintain the integrity and brightness of the lights over longer distances, ensuring consistent performance throughout your installation.

Can I choose the color of the aluminum channel for my InvisiLights kit?

Yes, you can select your preferred color for the aluminum channel to match your home’s exterior or personal taste. Please make sure to specify your color choice in the notes at checkout when you place your order.

How do the included components of the InvisiLights kit enhance the lighting system?

Each component in the InvisiLights kit plays a crucial role in creating an effective and stunning lighting display:

Aluminum Channels: Provide a durable, weather-resistant housing for the LED lights, which helps in maintaining a clean and nearly invisible look during the day.

RGBW LED Lights: Offer vibrant, full-spectrum color and white light combinations, making it perfect for any occasion from festive holidays to elegant ambient lighting.

Data Boosters: Ensure that the signal remains strong across longer distances, which is crucial for larger installations.

Power Supply: Designed to efficiently handle the energy needs of the system without overload, ensuring safety and durability.

GFCI Outlet Adapter: Adds an extra layer of safety by protecting against electrical shorts and surges, particularly important in outdoor settings.

Controller: Provides the flexibility to customize and control the lighting sequences, colors, and patterns right from your smartphone or controller, adding convenience and advanced functionality to your lighting system.

Can I use Invisilights year-round?

Absolutely! Invisilights are designed for versatile use throughout all seasons. Whether you're celebrating a special occasion, setting a mood for a party, Love your favorite sports team, or simply enhancing your home's ambiance, our lighting systems provide the perfect solution for any event, big or small.

Can I set timers and events for Invisilights?

Yes, Invisilights feature advanced programmable settings that allow you to schedule lighting for specific events and automate timers. This functionality ensures that your lighting preferences are perfectly aligned with your lifestyle, turning on and off at predetermined times without any manual intervention.

Is it possible to achieve warm or soft white with Invisilights?

Absolutely, Invisilights are equipped with RGBW technology, which includes a dedicated white LED alongside the standard red, green, and blue LEDs. This addition allows the system to produce authentic warm white, soft white, and various other shades of white with greater accuracy and intensity compared to traditional RGB systems. This capability ensures that you can effortlessly tailor the lighting to fit the desired ambiance and aesthetic of any environment, providing precise control over both vibrant colors and the subtlety of different white tones.

How do you ship your product?

Our products are shipped directly from our warehouse using reliable shipping carriers to ensure timely and safe delivery. Each product is securely packaged to prevent damage during transit, and we provide tracking information so you can follow your order’s journey to your doorstep.

Where are the controller and power supplies installed?

The controller and power supplies for Invisilights are typically installed in an accessible location such as a garage or utility room. These components connect to your home’s WiFi network, allowing seamless control over the lighting system via our user-friendly mobile app.

How long do Invisilights last?

Invisilights are engineered to last, with each LED bulb boasting a lifespan of over 50,000 hours. Given a typical usage of 10 hours per night, this translates to approximately 5,000 nights. This means your Invisilights could illuminate your home's exterior for nearly 14 years under these conditions, ensuring that your investment not only adds beauty but also long-term value to your property.

Are Invisilights dimmable?

Yes, all Invisilights are fully dimmable. This feature allows you to adjust the intensity of the light to suit various occasions, from a soft glow for a romantic evening to bright, vibrant colors for a festive celebration.

What types of custom channels are available?

Invisilights offers two types of custom channels, available in 40 different colors, ensuring a nearly invisible installation. These channels are designed to blend seamlessly with your home’s architecture, providing discreet yet effective lighting.

Can I control different zones independently?

Yes, the Invisilights system supports multiple zones which can be controlled independently or synchronized. This functionality allows for intricate lighting designs that can vary across different areas of your home, enhancing the overall impact and utility of your installation.

What is outdoor permanent lighting?

Permanent lighting refers to architectural-grade lighting systems that are installed permanently on your property to provide year-round illumination.

How does permanent lighting differ from traditional holiday lighting?

Unlike traditional holiday lighting, which is typically temporary and used only during specific seasons, permanent lighting is installed once and can be used throughout the year for various occasions

Discover Expert Tips on Our Blog

The Christmas Light Season Nobody Talks About (Raw Truth)

The Christmas lights installation business generates extraordinary revenue in compressed timeframes—some installers earn $100,000 in just seven days, while others generate six or seven figures in 8-12 weeks. This concentrated earning period creates life-changing financial opportunities, but it also produces crushing mental and physical exhaustion that threatens to destroy businesses from the inside out.

Burnout isn't a weakness—it's a predictable response to wearing every business hat simultaneously while working 12-14 hour days for weeks on end. The installer answering phones at 7 AM, climbing roofs until dark, managing employees, chasing payments, ordering materials, handling callbacks, and dealing with difficult customers experiences stress levels few other industries demand. Add weather delays, employee no-shows, family neglect, and financial anxiety over uncollected payments, and you have a recipe for complete breakdown.

This comprehensive guide addresses the reality of Christmas lights burnout that few discuss publicly, reveals why it happens and how to prevent it, provides systems for scaling without working yourself into the ground, and offers mindset shifts that separate sustainable six-figure businesses from one-season burnouts.

The Burnout Reality: What Nobody Talks About

Four conversations in one week revealed an identical pattern: successful installers generating $150,000-$200,000 saying "I'm burnt out, I'm exhausted, and I'm done."

The Common Thread in Burnout Stories

Conversation 1: Installer approaching $200,000 revenue, working solo without getting off the truck all season

Conversation 2: Business owner doing "everything"—sales, installation, callbacks, materials management, payments

Conversation 3: Installer with four crews getting 20+ leads daily but too overwhelmed to respond to half of them

Conversation 4: Solo operator working 14-hour days, seven days weekly, snapping at family who "just want to see me"

The pattern: revenue success accompanied by complete operational chaos and personal exhaustion.

Why Christmas Lights Creates Unique Burnout Risk

Compressed earning season: Generate entire year's income in 8-12 weeks instead of spreading over 12 months

Extreme weather vulnerability: Rain, snow, ice, and cold create installation delays that compress workload into fewer available days

Physical demands: Climbing ladders and walking roofs in freezing temperatures for 10-12 hours daily

Mental load: Simultaneously managing sales, operations, employees, materials, scheduling, payments, and customer service

Family sacrifice: Missing Thanksgiving, working weekends, arriving home after kids sleep, mental absence even when physically present

Financial stress: Hundreds of thousands in uncollected receivables sitting out while operating expenses mount

Equipment pressure: Wearing all hats because hiring feels riskier than just "doing it yourself"

One installer described it perfectly: "We start the season excited and energized. We end looking like skeletons—physically exhausted, mentally drained, emotionally depleted."

The Systems Problem: Why "Just Work Harder" Fails

Most burnout stems not from insufficient work ethic but from absent systems. Installers work harder, longer, and more intensely without addressing the structural problems causing overwhelm.

The One-Person Bottleneck

The installer who approached $200,000 revenue working entirely solo demonstrates the classic scaling failure. At some revenue level, adding hours becomes impossible—there are only 24 hours in a day.

The math that doesn't work:

Average ticket: $2,000

Jobs needed for $200,000: 100 jobs

Available installation days: 40-50 days (weather, scheduling)

Jobs per day required: 2-2.5 daily

Completing 2+ residential installations daily solo is physically impossible on most properties. The installer works sunrise to well past dark, six or seven days weekly, and still falls behind schedule.

The solution isn't working harder—it's hiring help. One quality crew member completing installations while the owner focuses on sales, scheduling, and quality control would have doubled revenue to $400,000 with less personal labor.

The "I Do Everything" Trap

Another common pattern: the business owner who refuses to delegate anything.

The owner simultaneously:

Answers every phone call personally

Creates every quote and mockup

Orders all materials and tracks inventory

Completes all installations (or manages crews on-site)

Handles all customer service and callbacks

Processes all payments and accounting

Manages all marketing and lead generation

This approach works fine at $50,000 revenue. At $150,000-$200,000, it creates chaos. At $500,000+, it's completely impossible.

The delegation hierarchy for scaling:

First hire: Installation crew member (removes you from daily physical labor)

Second hire: Office support (answers phones, sends quotes, schedules jobs, processes payments)

Third hire: Second installation crew (doubles installation capacity)

Fourth hire: Salesperson (removes you from quote generation and closing)

Fifth hire: Operations manager (coordinates crews, manages materials, handles logistics)

Most installers resist this progression because "I can't afford to hire anyone." The truth: you can't afford NOT to hire. Your time has a dollar value—if you earn $200,000 annually working 2,000 hours, your time is worth $100/hour. Every hour you spend on $20/hour tasks (answering phones, driving to supply stores, basic installation work) costs you $80 in opportunity cost.

The Lead Management Crisis

Multiple installers report receiving 20+ daily leads during peak season but only responding to half because they're "too busy installing."

This is business suicide. Each ignored lead cost money to generate (Facebook ads, yard signs, SEO investment). Ignoring leads is identical to lighting cash on fire.

The solution: Hire virtual assistant or part-time employee dedicated solely to lead response during peak season. For $15-$20/hour (approximately $1,200-$1,600 for entire season), this person:

Answers every call within minutes

Sends preliminary quotes within 60 minutes

Follows up on outstanding quotes systematically

Schedules installations and manages calendar

Processes payments and sends invoices

Cost: $1,500 for season. Value: Converting an additional 10-20 leads at $2,000 average ticket = $20,000-$40,000 additional revenue.

The ROI calculation isn't even close—it's overwhelmingly in favor of hiring help.

The Weather Stress Multiplier

Weather creates the variable installers cannot control, and it amplifies every other stress factor exponentially.

How Weather Destroys Schedules and Mental Health

Rain delays: Can't install safely on wet roofs. Every rain day pushes 2-3 scheduled jobs into an already-compressed timeline.

Snow complications: Some installers handle snow removal businesses, creating impossible choice between Christmas lights commitments and snow removal contracts.

Cold and ice: Frozen gutters, icy roofs, and brutal wind chills make installation dangerous and physically exhausting.

Compressed installation windows: Late November weather in many regions creates 10-15 day windows where installation is actually possible, forcing completion of 50+ jobs in impossibly short timeframes.

One installer perfectly summarized the dilemma: "I plow snow, but I have Christmas lights jobs scheduled. The snow needs to stop for two more weeks so I can finish lights, but I also need the snow income."

Managing Weather-Related Stress

Strategy 1: Build weather delays into pricing and scheduling

Don't schedule every available day. Build 20-30% weather buffer into schedules. If you have 40 potential installation days, only schedule 28-30 jobs initially. Weather delays fill the buffer days rather than creating cascade failures.

Strategy 2: Implement "first available" scheduling for weather delays

Instead of rescheduling specific dates after weather delays, move affected customers to "first available" status. This prevents the domino effect where one rain day requires rescheduling 20+ specific appointments.

Strategy 3: Use weather delays for quote follow-up and administrative work

Rain days are perfect for texting every outstanding quote, processing payments, ordering materials, and handling administrative tasks that get neglected during installation days.

Strategy 4: Invest in equipment enabling installation in marginal conditions

Boom lifts allow installation during conditions where roof access is impossible. The $4,000 seasonal rental cost seems expensive until you calculate the $20,000-$30,000 in jobs completed that would otherwise be cancelled or delayed.

The Employee Management Challenge

Employee issues rank among the top stressors during Christmas lights season—and many are self-inflicted through poor hiring, inadequate training, and unrealistic expectations.

Why "I Can't Find Good Workers" Is Usually Wrong

The installer who complains "you just can't find good workers today" typically:

Pays below-market rates ($15-$18/hour when McDonald's pays $25+)

Provides zero training beyond "figure it out"

Treats employees as disposable labor rather than valuable team members

Offers no appreciation, recognition, or positive feedback

Creates chaotic schedules with constant last-minute changes

Blames employees for failures caused by absent systems

The reality: Good workers exist everywhere. But good workers won't tolerate poor leadership, low pay, absent training, and chaotic operations.

The High-Performance Employee Formula

Pay competitively: $20-$25/hour minimum for experienced installers, $50+ per job for piece-rate work

Train systematically: Create video library showing every installation technique. Test knowledge with quizzes. Document training completion.

Treat professionally: Respect, appreciation, consistent communication, reliable schedules

Provide quality equipment: Professional trucks, proper safety gear (Cougar Paws, harnesses, pitch hoppers), quality tools

Implement performance bonuses: $50-$100 bonus for jobs completed without callbacks, customer satisfaction ratings above 4.5/5, safety compliance

Recognition and appreciation: Public praise for excellent work, thank-you messages, end-of-season bonuses

One installer noted: "I thought hiring help would cost me money. Instead, hiring one good crew member doubled my revenue because I could focus on sales and scheduling instead of installing everything myself."

The Two-Hour Hiring Story

An installer put out a Facebook post offering free business coaching during a six-hour drive. One person called. They talked for two hours.

The lesson: Most people want success handed to them without taking uncomfortable action. The one person who called got two hours of valuable coaching while everyone else scrolled past hoping success would magically appear.

The same principle applies to your business. Most people want $200,000 revenue without:

Making uncomfortable sales calls

investing money in marketing

Hiring help and trusting employees

Creating videos despite hating how they sound

Door-knocking neighborhoods

Posting daily on social media

Working 70-hour weeks during peak season

The installers earning six and seven figures do all those uncomfortable things. The installers stuck at $30,000-$50,000 do none of them.

The Mindset Shifts That Prevent Burnout

Burnout is partly physical exhaustion but primarily mental overwhelm. Changing how you think about your business changes your stress levels dramatically.

Shift 1: From "I Have to Do Everything" to "I Enable Others to Excel"

Old mindset: "Nobody can do this as well as I can, so I have to do everything myself."

New mindset: "My job is creating systems that enable others to do excellent work without me."

Your role isn't being the best installer—it's building a business that operates excellently whether you're present or not.

Shift 2: From "I Can't Afford Help" to "I Can't Afford NOT to Have Help"

Old mindset: "I can't afford to pay someone $20/hour when I'm only making $30/hour myself."

New mindset: "Paying someone $20/hour to complete installations frees me to sell jobs. I close $10,000 daily in new sales working the phones while my installer completes $4,000 in installations. Total daily revenue: $14,000. Without help: $2,000-$4,000."

The math always favors hiring once you calculate opportunity cost correctly.

Shift 3: From "I'm Too Busy" to "I'm Working on the Wrong Things"

Old mindset: "I'm too busy installing to respond to leads, follow up on quotes, or handle administrative work."

New mindset: "If I'm too busy installing to do sales and marketing, I'm working IN my business instead of ON my business. I need to hire installers so I can focus on revenue generation."

Being busy doesn't equal being productive. You can be busy all day with $20/hour tasks while neglecting $200/hour tasks that actually grow revenue.

Shift 4: From "This Customer Is Terrible" to "I Attracted the Wrong Customer"

Old mindset: "All my customers are cheap, demanding, and unreasonable."

New mindset: "I'm charging $6/foot and marketing to everyone. Of course I attract price-shopping problem customers. If I charge $10-$12/foot and target affluent neighborhoods, I'll attract customers who value quality and service."

Your pricing and marketing determine your customer quality. Bad customers are usually symptoms of underpricing and poor targeting.

The Price Psychology Breakthrough

One installer shared: "I thought you were lying when you said to charge $10/foot. I was stuck at $5/foot. I changed to $8-$12/foot and customers still buy—I just feel less stressed because I'm actually making profit."

Another: "I barely charged $6 first year and made no profit. Year two, I charged $8-$12 and was shocked how many people said yes. I 2.5x my revenue by simply changing my pricing."

The pattern repeats endlessly: Installers convinced their market "won't pay more than $X" who discover customers happily pay 50-100% more once the installer believes they're worth it.

The mental block isn't customer willingness—it's installer confidence. When you don't believe you're worth $10/foot, customers sense that uncertainty and negotiate down. When you confidently present $12/foot pricing, customers accept it as the market rate.

How do I avoid burnout when I'm the only person who can do installations?

You avoid burnout by not being the only person who can do installations. This requires proactive hiring before burnout hits—typically when you're scheduling 10+ jobs weekly. Hire experienced roofers first (they're already comfortable on roofs and understand safety). Train them on Christmas lights specifics using video libraries and supervised installations. Start them on simple properties while you handle complex jobs. Gradually transfer more installations to them while you focus on sales, scheduling, and business management. The investment in hiring and training pays for itself within 2-3 weeks.

What's the minimum revenue level where I should hire my first employee?

Hire your first installation helper at $50,000-$75,000 revenue or when you're consistently working 60+ hours weekly. The calculation: if hiring someone at $20-$25/hour enables you to close an additional 10-20 jobs at $2,000 average ticket, they generate $20,000-$40,000 additional revenue while costing $4,000-$6,000 in wages for the season. That's 300-1000% ROI. Don't wait until burnout forces the decision—hire proactively when growth trajectory justifies it.

How do I find reliable employees during Christmas lights season when everyone is busy?

Target roofers, construction workers, and landscapers whose primary business slows during winter. Post in roofing Facebook groups, construction trade groups, and local employment boards emphasizing "seasonal work, November-December, $20-$25/hour, flexible schedule." Offer competitive wages ($20-$25/hour minimum—remember McDonald's pays that much now). Provide quality equipment and professional environment. Train systematically using videos and supervised installations. Treat employees with respect and appreciation. The "worker shortage" largely exists among businesses offering low wages, poor treatment, and chaotic operations.

What systems prevent employee problems from creating more stress than they solve?

Create video training library covering every installation technique, safety protocol, and customer service expectation. Test comprehension with quizzes before allowing independent work. Implement checklists for every installation stage. Use quality control inspections (you or senior installer) before leaving properties. Pay piece-rate ($0.80-$1.25/foot) rather than hourly to incentivize efficiency and quality. Provide bonus structure rewarding no-callback jobs and high customer satisfaction. Document everything—training completion, safety briefings, performance issues. This documentation protects you legally and creates accountability.

How do I manage the mental stress of uncollected payments while trying to install?

Implement deposits and payment systems preventing this problem: require 50% deposit at booking (secures schedule, covers materials), collect remaining 50% immediately after installation completion before leaving property. Use Jobber, ServiceTitan, or similar CRM with integrated payment processing enabling tap-to-pay on phones. For customers unable to pay immediately, use financing options (Jobber offers this) enabling customer approval in minutes. Never leave properties without payment unless you have signed financing agreement. The stress of chasing $100,000+ in receivables destroys mental health—eliminate it through systematic payment collection.

Should I turn down leads when I'm already fully booked, or try to schedule them further out?

Send quotes immediately even if you're fully booked. Use premium pricing ($12-$15/foot instead of standard $10/foot) for jobs requiring rush scheduling or dates beyond your typical season end. Many customers will pay premiums for December installations. Capture contact information for leads you can't serve and convert them to 2026 pre-bookings with early-bird discounts. Subcontract overflow to trusted installers and take referral fees. Never simply ignore leads—you paid to generate them, and ignoring them wastes marketing dollars while potentially damaging reputation through non-responsiveness.

How do I balance family time when Christmas lights demands 12-14 hour days for weeks?

Set boundaries proactively: designate one day weekly as family day with zero work (even if it means turning down jobs or delaying installations). Communicate openly with family about the compressed earning season and what it enables (financial security, family vacations, time freedom remaining 10 months). Include family in celebrations of milestones ("we hit $100,000 today!"). Block evenings 6-8 PM for family dinner even if you return to administrative work afterward. Recognize the sacrifice family makes and express appreciation consistently. Remember: you're doing this FOR family financial security, but destroying family relationships in the process defeats the purpose.

What's the best way to handle weather delays that compress my schedule impossibly?

Build 20-30% buffer into initial scheduling—if you have 40 available installation days, schedule only 28-30 jobs initially so weather delays fill buffer rather than creating cascade failures. Use "first available" rescheduling rather than specific dates (prevents domino effect requiring 20+ rescheduling calls). Communicate proactively with customers about weather delays before they call you. Consider boom lift rental ($4,000 season) enabling installation in conditions where roof access is impossible. Use weather delay days for administrative work, quote follow-up, and material organization. Accept that some weather delays are unavoidable—the stress comes from trying to control uncontrollable factors.

How do I know if I'm underpricing and that's contributing to my stress?

If you're closing 30%+ of quotes, you're underpriced. Premium services targeting affluent customers typically close 15-25% of leads—higher rates indicate you're not filtering out price shoppers effectively. If you're working constantly but barely profitable, you're underpriced. If customers rarely question your pricing, you're underpriced. If you have more demand than installation capacity, you're underpriced. Calculate true costs: materials + labor + insurance + marketing + equipment + overhead + profit margin. Most installers discovering they're working for $15-$20/hour after all costs—that's underpricing driving burnout through overwork with insufficient profit.

Can I really grow to $200,000-$500,000 without working myself to death?

Yes—but only with systems and help. Solo installers can reasonably handle $75,000-$100,000 annually. Beyond that requires hiring. The path: first hire enables $150,000-$200,000, second hire enables $250,000-$350,000, third hire enables $400,000-$500,000+. Most burnout happens when revenue goals don't align with staffing reality. Plan hiring around growth targets: "I want $300,000 revenue next year. That requires 2-3 installation crews plus office support plus sales help. I'll need to invest $30,000-$50,000 in labor costs." This planning prevents the "I'm doing $200,000 solo and dying" scenario.

Copyright ©2026 All Right Reserved website designed by christmaslights.io

Terms of Service / Privacy Policy

Have questions or need assistance?

Contact us at (855)619-LITE