C9 & C7 Socket Spools & Stringers

Discover our premium collection of socket wire spools and stringers, the essential foundation for creating stunning light displays. Designed for both professional installers and ambitious homeowners, our range includes bulk C7 and C9 socket wire spools with flexible spacing options, pre-made light stringers for quick setups, and convenient accessories like spool holders. These versatile, durable components are perfect for residential rooflines, enchanting tree displays, and large-scale commercial projects. Suitable for indoor and outdoor use, and compatible with both incandescent and LED bulbs, our professional-grade products offer the quality and flexibility needed to bring your creative lighting visions to life. Explore our selection and elevate your illumination projects with unmatched versatility and reliability.

Socket Spools

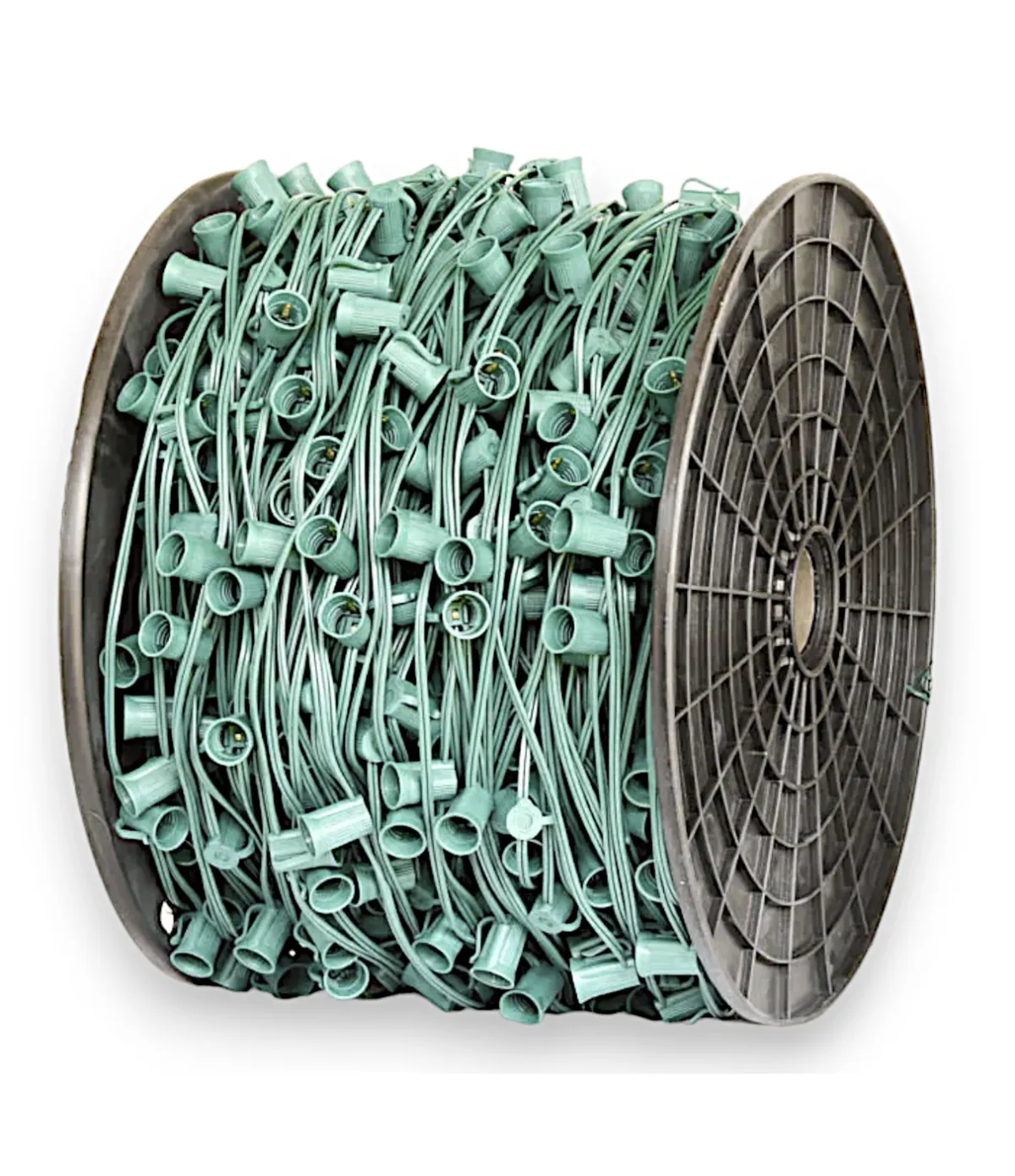

C9 1000' Socket Spool

Our C9 1000' Bulk Spool of Socket Wire, available in green or white, offers professional-grade flexibility for custom lighting projects. With spacing options from 6" to 48", it's ideal for both residential rooflines (12-15" spacing) and tree installations (24-48" spacing). The durable SPT-1 wire withstands outdoor conditions and is compatible with both incandescent and LED C9 bulbs. This customizable spool allows for precise length cutting, minimizing waste and maximizing efficiency for high-quality, adaptable lighting displays.

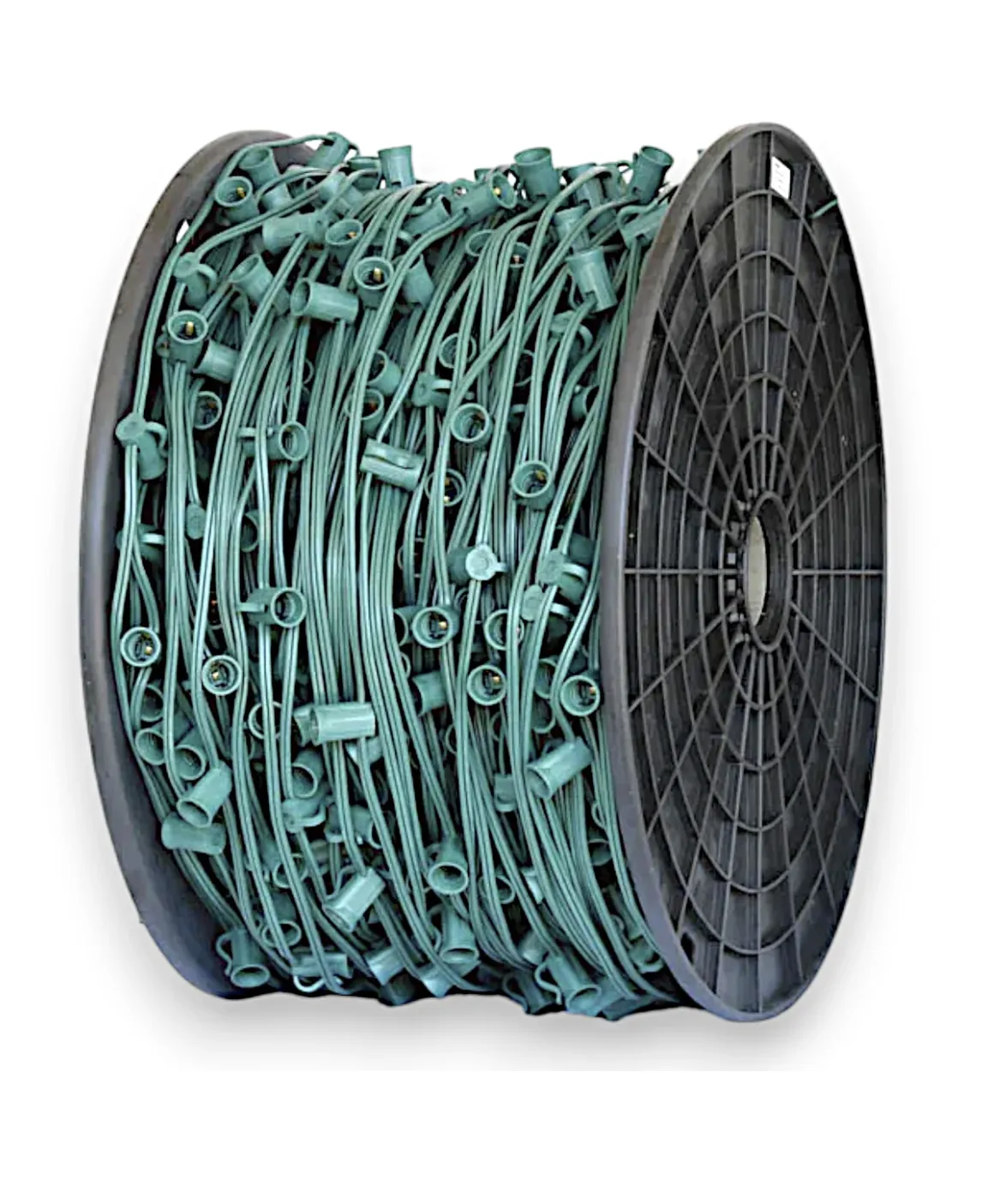

C9 500' Socket Spool

Our C9 500' Bulk Spool of Green Wire, available with 12" (500 sockets) or 15" (400 sockets) spacing, is perfect for professional-grade Christmas lighting installations. Featuring commercial-quality SPT-1, 8-amp wire and durable E17 sockets, this customizable spool is ideal for large-scale outdoor projects. Easily cut to desired lengths and pair with snap-on plugs (sold separately) for tailored lighting solutions in both residential and commercial settings. The 12" spacing offers vibrant, balanced lighting, while the 15" option provides a classic look with fewer bulbs per run.

C9 1000' 12"&15" Socket Wire Spool (SPT-2)

Our C9 1000' Socket Wire Spool (SPT-2) offers professional-grade flexibility with dual 12" and 15" spacing options. This customizable spool features heavy-duty SPT-2 wire for enhanced durability in all weather conditions. The 12" spacing is perfect for dense, vibrant displays on rooflines and pathways, while the 15" option provides a classic look with fewer bulbs per run. Compatible with both incandescent and LED C9 bulbs, this 1000' spool allows for precise cutting to fit any residential or commercial lighting project, ensuring efficient and long-lasting installations.

C7 1000' Green Wire Socket Spool (SPT-2)

Our 1000' bulk spool of green SPT-2 wire features 15" spacing with 1000 C7 sockets, ideal for commercial and residential outdoor displays. This 8-amp (960-watt) commercial-grade wire with Admiral Brand sockets allows for custom-length installations using snap-on plugs (sold separately). Suitable for indoor/outdoor use, it accommodates up to 160 sockets with 5-watt incandescent bulbs or 384 sockets with 1-watt LED bulbs per run. This versatile, durable C7 light line is perfect for creating professional-quality lighting displays in various settings.

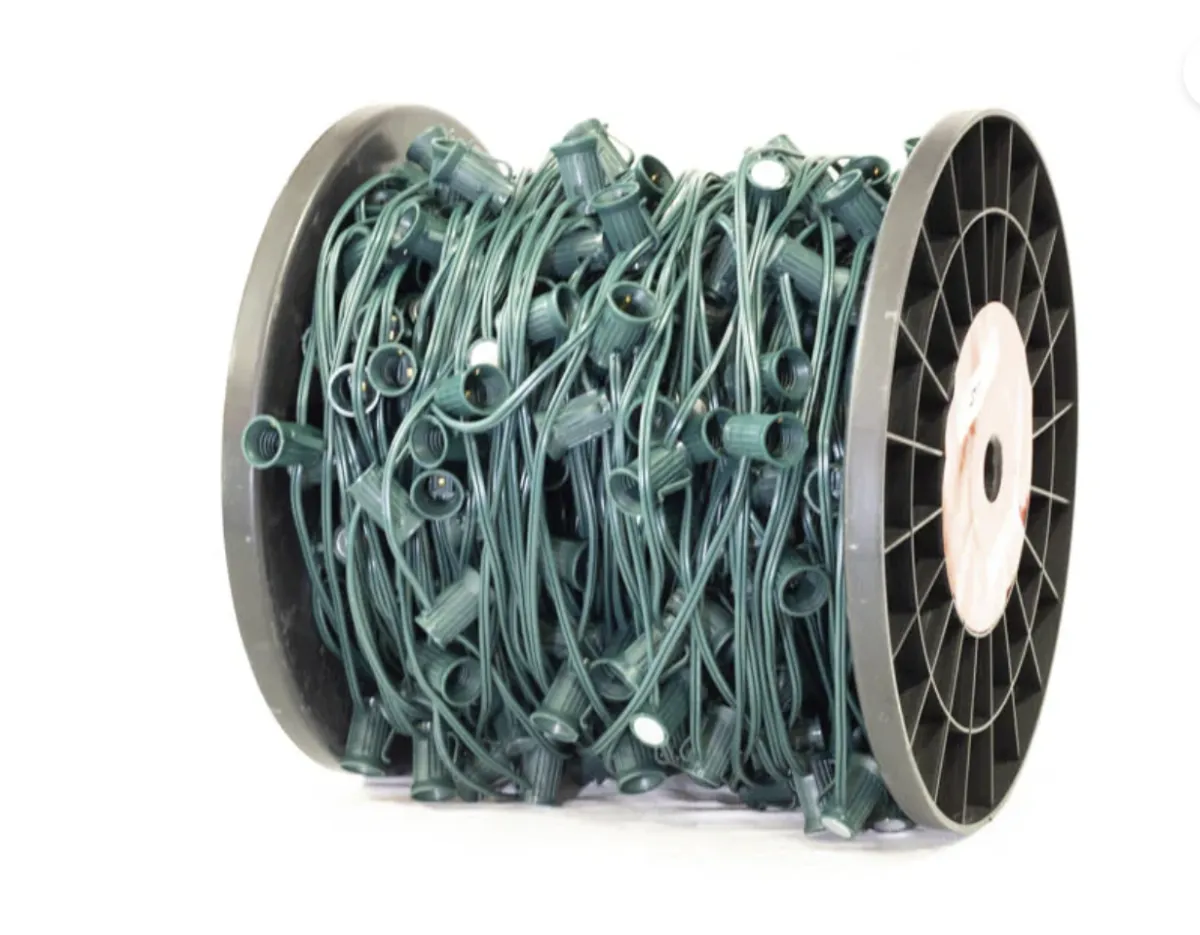

C7 1000' Socket Spool

Our C7 1000' Bulk Spool of Socket Wire offers professional-grade flexibility for custom lighting projects. Available in green or white, with spacing options from 12" to 36", it's ideal for both residential rooflines (12-15" spacing) and tree installations (24-36" spacing). The durable SPT-1 wire withstands outdoor conditions and is compatible with both incandescent and LED C7 bulbs. This customizable spool allows for precise length cutting, minimizing waste and maximizing efficiency for high-quality, adaptable lighting displays in various settings.

C9/C7 500' Magnetic Spool

The Fastest Way to Install Holiday Lights on Metal Surfaces. Save time and effort this holiday season with Magnetic Spools. Designed for quick and easy installation, these magnetic spools are perfect for decorating your home or office building. The magnetic sockets eliminate the need for traditional mounting clips, making your installations faster and more efficient. Whether you’re lining rooflines, gutters, or fences, these spools are ideal for any surface where ferrous metal is present.

Available in 500' & 250', 12" or 15" Spacing.

Socket Wire Stringers

C9 12" Spacing Socket Wire Stringers

Our 25', 50' or 100' Holiday Light String features professional-grade, UV-protected 18-gauge wire with sockets spaced 12" apart. Designed for both indoor and outdoor use, these UL-recognized strings offer 5 Amp capacity SPT-1 insulation and durable sockets with weep holes for all-weather performance. Compatible with E12 Candelabra base bulbs (C7, C9, G30; sold separately), these versatile strings allow end-to-end connectivity for extended displays. Perfect for holiday decorations, event lighting, and year-round use in residential and commercial settings. Available in Green, White, Brown and Black.

C7 12" Spacing Socket Wire Stringers

Our professional-grade 25', 50' or 100' light string features sockets spaced 12" apart, perfect for commercial and residential decorators. Designed for both indoor and outdoor use, it's compatible with incandescent or LED C7, G30, and G40 bulbs (sold separately). The SPT-1 insulated wire offers 5 Amp capacity and includes weep-hole sockets for all-weather performance. With male and female plugs for end-to-end connections, these UL-recognized strings can handle up to 480 watts per run. Ideal for holiday displays, patio lighting, and year-round events, these durable strings ensure long-lasting, brilliant illumination for any occasion. Available in Green, White, Brown and Black.

Frequently Asked Questions

What's the difference between socket wire spools and stringers?

cket wire spools are bulk reels of wire with sockets at regular intervals, allowing for custom-length cuts. Stringers are pre-cut lengths of socket wire, typically with plugs attached, ready for immediate use.

Can I use the same socket wire for both C7 and C9 bulbs?

No, C7 and C9 bulbs require different socket sizes. Always check the product specifications to ensure you're using the correct socket wire for your chosen bulb type.

How do I determine the right spacing for my project?

Common spacings are 12", 15", and 24". Use closer spacing (12"-15") for dense, vibrant displays on rooflines or fences. Wider spacing (24" or more) works well for tree wrapping or creating a more subtle effect.

Are these socket wires suitable for outdoor use?

Most of our socket wires are rated for both indoor and outdoor use. Look for products labeled as "weatherproof" or "outdoor-rated" for the best durability in external conditions.

How many bulbs can I safely connect on a single run?

This depends on the wire's amperage rating and the wattage of your bulbs. For example, on an 8-amp wire, you can typically run up to 160 sockets with 5-watt incandescent bulbs or 384 sockets with 1-watt LED bulbs. Always check the product specifications and local electrical codes for safe operation.

Discover Expert Tips on Our Blog

Deck the Halls Without the Falls: A Comprehensive Guide to Fall Protection for Christmas Light Installers

As a professional Christmas light installer, your job is to bring joy and holiday cheer to homes and businesses. However, this line of work comes with inherent risks, particularly when it comes to working at heights. Falls are a leading cause of injuries and fatalities in the construction industry, and Christmas light installers are no exception. In this blog post, we'll explore essential fall protection strategies to help keep you safe on the job.

Understanding the Risks

Before we dive into fall protection strategies, it's crucial to understand the risks involved in Christmas light installation. Common causes of falls include overreaching, improper ladder use, and lack of proper equipment. According to the Occupational Safety and Health Administration (OSHA), falls account for nearly one-third of all construction-related fatalities. The consequences of a fall can be severe, ranging from broken bones and head injuries to permanent disability and even death. Additionally, falls can lead to legal issues and financial losses for both the installer and the company.

Proper Equipment

One of the most important aspects of fall protection is using the proper equipment. A Personal Fall Arrest System (PFAS) is a must-have for any Christmas light installer working at heights. A PFAS consists of three main components: a harness, a lanyard, and an anchor point. The harness should fit snugly and be worn correctly, with the straps adjusted to distribute weight evenly. The lanyard connects the harness to the anchor point and should be short enough to prevent the worker from hitting the ground in case of a fall. The anchor point must be strong enough to support the weight of the worker and the fall arrest system.

Ladders are another essential piece of equipment for Christmas light installers. Choosing the right ladder for the job is crucial. Stepladders are suitable for shorter heights, while extension ladders are better for reaching higher elevations. When using a ladder, always follow safety guidelines, such as maintaining three points of contact, keeping the ladder on level ground, and avoiding overreaching.

For larger projects or hard-to-reach areas, scaffolding or lifts may be necessary. There are various types of scaffolding and lifts available, each with its own safety guidelines. Always follow the manufacturer's instructions and OSHA regulations when using scaffolding or lifts.

Training and Education

Proper training and education are essential for ensuring the safety of Christmas light installers. OSHA requires employers to provide fall protection training to workers exposed to fall hazards. This training should cover topics such as identifying fall hazards, using fall protection equipment, and following safe work practices. In-house training programs can be tailored to the specific needs of the company and its employees.

Continuing education and refresher courses, such as those offered by Christmaslights.io: Online & In-Person Christmas Lights Training and Supplies are crucial for Christmas light installers to maintain their skills and stay informed about the latest safety regulations in the industry. These training programs help professionals keep their knowledge fresh, learn about new techniques and equipment, and ensure they are following best practices on the job. Employers should prioritize and support ongoing training for their Christmas light installers to foster a culture of safety, reduce the risk of accidents, and maintain a highly skilled workforce.

Job Site Assessment and Planning

Before starting any Christmas light installation project, it's essential to conduct a thorough job site assessment. This involves identifying potential fall hazards, such as unstable surfaces, overhead power lines, and weather conditions. Based on the assessment, a fall protection plan should be developed, outlining the specific equipment and procedures needed to mitigate the identified risks.

Communication and coordination with the entire team are crucial during the planning phase. Everyone involved in the project should be aware of the fall protection plan and their individual roles and responsibilities.

Best Practices During Installation

During the actual installation process, Christmas light installers must follow best practices to ensure their safety. This includes properly using fall protection equipment, following safe ladder usage techniques, and maintaining three points of contact when climbing or descending.

Working in pairs or teams can also enhance safety, as co-workers can spot each other and provide assistance in case of an emergency. It's important to manage fatigue and take regular breaks to avoid mistakes and accidents caused by exhaustion.

Emergency Response and Rescue

Despite our best efforts, accidents can still happen. That's why it's crucial to have an emergency response plan in place. This plan should outline the steps to take in case of a fall or other emergency, including contacting emergency services and providing first aid.

All employees should be trained on emergency procedures and know their roles in the event of an incident. Providing first aid and CPR training to team members can also be lifesaving. Coordination with local emergency services, such as fire departments and ambulance services, can help ensure a swift and effective response in case of an emergency.

Maintenance and Inspection

Fall protection equipment is only effective if it's well-maintained and inspected regularly. Employers should establish a schedule for inspecting harnesses, lanyards, and anchor points, looking for signs of wear, damage, or defects. Any equipment that shows signs of deterioration should be removed from service immediately and replaced.

Proper storage and care of equipment can also extend its lifespan and ensure it's ready for use when needed. Documenting inspections and maintenance can help track the condition of equipment and identify any patterns or issues that need to be addressed.

Creating a Culture of Safety

Ultimately, the success of any fall protection program depends on creating a strong culture of safety within the organization. Management must lead by example, prioritizing safety in all aspects of the business. This includes providing the necessary resources, such as equipment and training, and regularly communicating the importance of safety to employees.

Encouraging employee participation and feedback can also foster a sense of ownership and responsibility for safety. Recognizing and rewarding safe behavior, such as through incentive programs or public acknowledgment, can reinforce the importance of following safety protocols.

Continuously improving safety practices through regular reviews, incident investigations, and employee input can help identify areas for improvement and ensure that the fall protection program remains effective over time.

As a professional Christmas light installer, your safety should always be a top priority. By understanding the risks, using proper equipment, receiving adequate training, and following best practices, you can significantly reduce the likelihood of falls and other accidents on the job.

Remember, fall protection is not a one-time event but an ongoing process that requires commitment from everyone in the organization. By implementing these essential fall protection strategies and creating a strong culture of safety, you can ensure that you and your colleagues go home safely at the end of each day, ready to spread more holiday cheer.

Q: What are the common causes of falls during Christmas light installation?

A: Common causes of falls include overreaching, improper ladder use, and lack of proper equipment.

Q: What is a Personal Fall Arrest System (PFAS), and what are its components?

A: A PFAS is a must-have for any Christmas light installer working at heights. It consists of three main components: a harness, a lanyard, and an anchor point.

Q: What should I consider when choosing a ladder for Christmas light installation?

A: When choosing a ladder, consider the height you need to reach. Stepladders are suitable for shorter heights, while extension ladders are better for reaching higher elevations. Always follow safety guidelines when using ladders.

Q: What does OSHA require in terms of fall protection training for workers?

A: OSHA requires employers to provide fall protection training to workers exposed to fall hazards. This training should cover topics such as identifying fall hazards, using fall protection equipment, and following safe work practices.

Q: Why is job site assessment important before starting a Christmas light installation project?

A: A thorough job site assessment helps identify potential fall hazards, such as unstable surfaces, overhead power lines, and weather conditions. This information is essential for developing a fall protection plan and ensuring worker safety.

Q: What are some best practices to follow during Christmas light installation?

A: Best practices include properly using fall protection equipment, following safe ladder usage techniques, maintaining three points of contact when climbing or descending, working in pairs or teams, and managing fatigue by taking regular breaks.

Q: Why is it crucial to have an emergency response plan in place?

A: Despite best efforts, accidents can still happen. An emergency response plan outlines the steps to take in case of a fall or other emergency, including contacting emergency services and providing first aid. It ensures a swift and effective response in case of an incident.

Q: How often should fall protection equipment be inspected?

A: Employers should establish a schedule for inspecting harnesses, lanyards, and anchor points, looking for signs of wear, damage, or defects. Any equipment that shows signs of deterioration should be removed from service immediately and replaced

Q: Why are continuing education and refresher courses important for Christmas light installers?

A: Continuing education and refresher courses help Christmas light installers maintain their skills, stay informed about the latest safety regulations, learn about new techniques and equipment, and ensure they are following best practices on the job.

Q: What kind of training programs are available for Christmas light installers?

A: Training programs like those offered by Christmaslights.io: Online & In-Person Christmas Lights Training and Supplies provide Christmas light installers with opportunities for continuing education and refresher courses.

Q: How do these training programs benefit professionals in the Christmas light installation industry?

A: These training programs help professionals keep their knowledge fresh, learn about new techniques and equipment, and ensure they are following best practices on the job.

Q: What role should employers play in supporting ongoing training for their Christmas light installers?

A: Employers should prioritize and support ongoing training for their Christmas light installers to foster a culture of safety, reduce the risk of accidents, and maintain a highly skilled workforce.

Q: What are the benefits of employers investing in ongoing training for their Christmas light installers?

A: By investing in ongoing training, employers can foster a culture of safety, reduce the risk of accidents, and maintain a highly skilled workforce in the Christmas light installation industry.

Copyright ©2025 All Right Reserved website designed by christmaslights.io

Terms of Service / Privacy Policy

Have questions or need assistance?

Contact us at (855)619-LITE